Process Engineering Of Size Reduction Ball Milling

Process Engineering Of Size Reduction Ball Milling FREE PROCESS ENGINEERING OF SIZE REDUCTION BALL MILLING DOWNLOAD The best ebooks about Process .

WhatsApp)

WhatsApp)

Process Engineering Of Size Reduction Ball Milling FREE PROCESS ENGINEERING OF SIZE REDUCTION BALL MILLING DOWNLOAD The best ebooks about Process .

Preparation and characterization of high T c (1−x) BiScO 3−xPbTiO 3 ceramics from high energy ball milling process Lin Zhang Zhuo Xu Zhenrong Li Song Xia ...

In this investigation, the chemical and structural characteristics of Fe nanoparticles synthesized by highenergy ball milling have been explored.

of ball milling process on the electromagnetic parameters, there are different rules, even contradictory results. This may be related to the

Ball Milling An efficient and ... What is ball milling? A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 . ... process Tip of

Ball Milling University of Massachusetts Boston. What is ball milling? A ball mill is a type of grinder used to grind materials into extremely fine powder.

Scalable Exfoliation Process for Highly Soluble Boron Nitride Nanoplatelets by HydroxideAssisted Ball Milling

The Milling process. 3 5 ... animation 8 Milling Machine Tools Types ... Ballend mills make rounded pockets or spherical pockets; also fillets

Ball Milling Pdf download – files. Ball Milling Pdf – Microstructural composite mullite derived from oxides via a high energy ball milling process pdf ...

High energy ball milling process for nanomaterial . During the highenergy ball milling process, ... the milling efficiency of the planetary ball was found to be ...

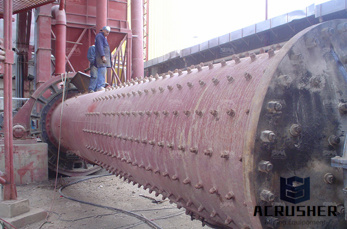

Ball Mill Process. It is necessary for ... Ball mill technology is one of the most commonly preferred types of machinery in the mining and milling industries.

HIGH ENERGY BALL MILLING A PROMISING ROUTE FOR PRODUCTION OF TAILORED THERMAL SPRAY CONSUMABLES A. WANK, B. WIELAGE Institute of .

Ball mill ½ and larger ... than 100:1 requires a twostep milling process. The first step should rely on larger media to reduce particle size to a level that can be ...

UNION PROCESS INC. Akron, Ohio ... THEORY OF MEDIA MILLING ... Ball mills are one of the more common mills and use a closed cylindrical container that is

Magnetic nanoparticles produced by surfactantassisted ball milling V. M. Chakka, ... Milling process and handling of the starting

LargeScale Production of EdgeSelectively Functionalized Graphene Nanoplatelets via Ball Milling and Their Use as MetalFree Electrocatalysts for Oxygen Reduction ...

Upgrade your ball mill process by switching to a three roll mill. Common issues in ball milling . ... a ball milling process and offer dramatic improvements in

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Solutions in Milling Sieving Size reduction and homogenization with ball mills RETSCH Product Navigator Milling Jaw Crushers Rotor Mills Cutting Mills

Milling Tools Inserts. ... TWINCUT Ball Nose Copy Mills 63 ... Plunge Milling Face Milling Pocket Milling/Ramping Shoulder Milling

How to Use a Ball Mill Safely and Effectively ... ball milling is the best way for the amateur fireworker to reduce particle size in their chemicals.

October 2001 Materials Letters 51 2001 139–143Ž. rr Fabrication of aluminum flake powder from foil scrap by a wet ball milling process Hong), Kim

EFFECT OF BALL SIZE DISTRIBUTION ON MILLING PARAMETERS François Mulenga Katubilwa A dissertation submitted to the Faculty of Engineering and the Built .

ball milling process pdf. Mechanical alloying in a planety ball mill: kinematic HAL Based on a kinematic modeling of the planetary ball mill, the kinematic ...

WhatsApp)

WhatsApp)